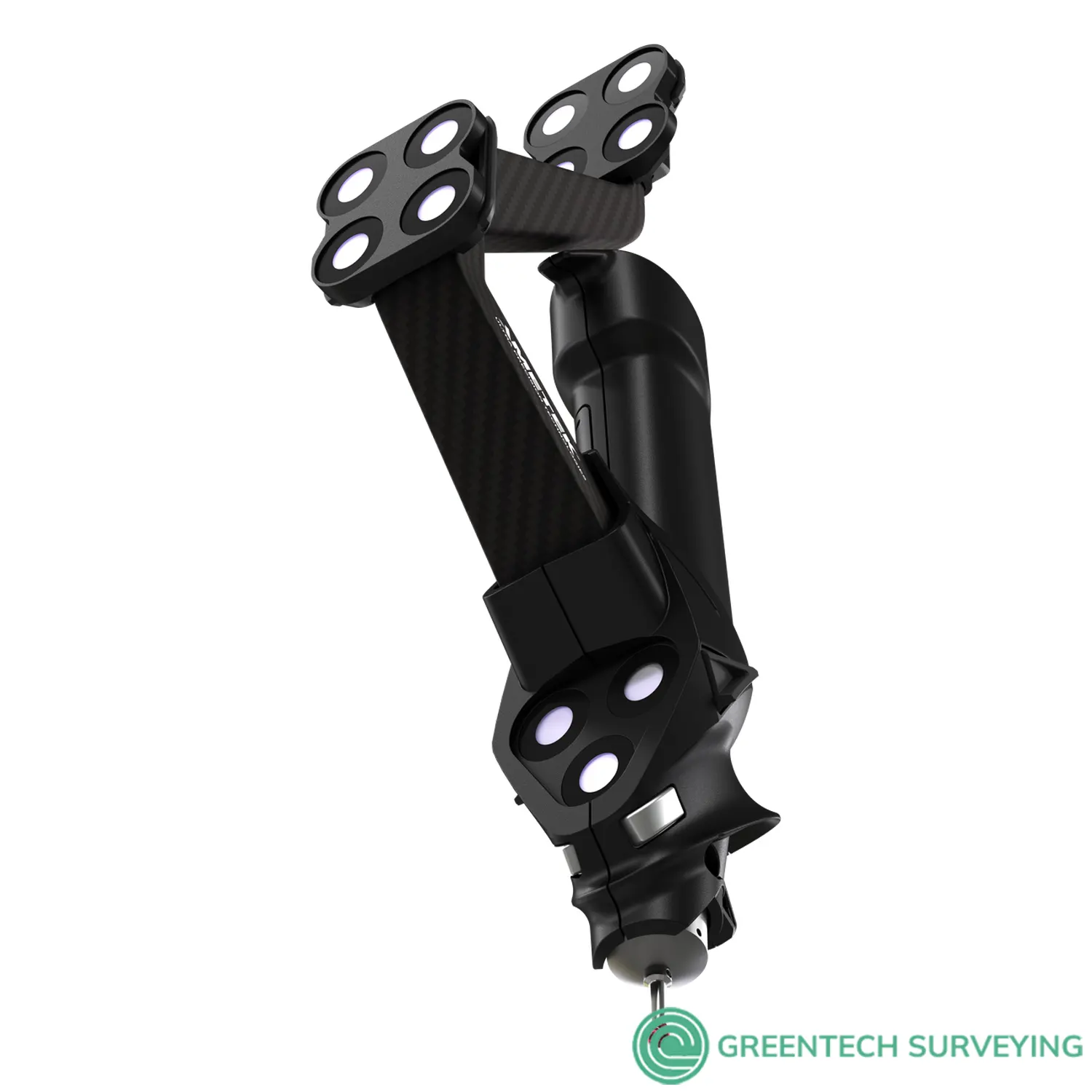

HandyPROBE Next C-Track Optical CMM

HandyPROBE Next + C-Track Optical CMM for sale, brand new 12-month Customer Care Program, Creaform C-Track Optical CMM (4th Generation), VXelements data acquisition software license

$25,000

HandyPROBE Next + C-Track Optical CMM for sale, brand new 12-month Customer Care Program, Creaform C-Track Optical CMM (4th Generation), VXelements data acquisition software license

Package includes;

- Creaform HandyPROBE Next Arm-Free Shop Floor Probing System

- Creaform C-Track Optical CMM (4th Generation)

- VXelements data acquisition software

- Power Supply + Custom Cables

- Portable Tripod for C-Track

- Calibration Kit

- Interactive E-learning Subscription

- Carrying Case

- 12-month Customer Care Program

The HandyPROBE Next portable CMM provides measurement accuracy that is insensitive to the instabilities of any environment. Free of any rigid measurement setup, the portable CMM outperforms traditional portable CMMs on the shop floor. The C-Track optical tracker and wireless probe can be moved at any time during the measurement sequence and generate the same high-quality data.

Accuracy and simplicity combined with portability

The HandyPROBE line-up is a portable optical CMM specifically designed for use on the shop floor. Thanks to its metrology-grade accuracy and dynamic referencing capabilities, the HandyPROBE delivers unmatched accuracy regardless of the measurement setup, instabilities of the environment and user experience level.

Without the requirements of a rigid measurement setup, the complete measuring system—the part, optical tracker, and wireless probe—can all be moved freely at any time during the measurement sequence.

The HandyPROBE is simply the best metrology solution for measuring geometrical entities on parts of any size directly on the production floor.

Achieve Metrology-grade Accuracy

The HandyPROBE is your go-to portable optical CMM to acquire highly accurate, reliable and repeatable 3D measurements—right on the shop floor.

- Dynamic referencing: Optical reflectors ensure that accuracy is never compromised because of shop floor conditions.

- Reliable acceptance test: The HandyPROBE’s acceptance test follows the ISO 10360-12 standard and is ISO 17025 accredited.

- Measure parts with a wide range of sizes: Get accurate measurements of parts ranging from 0.2 to 6 meters (0.7 to 20 feet) in size.

- Metrology-grade measurements: Benefit from an accuracy of 0.025 mm (0.0009 in) with a traceable certificate.

- Consistent accuracy over time: No accuracy drift over time in your quality control workflows thanks to an easy field calibration procedure.

Take it Anywhere. Use it Anywhere.

Because there is no physical link between the probe and system, the HandyPROBE can easily be brought to wherever the part is for maximum adaptability.

- Arm-free system: Tackle any inspection, anywhere, with ease thanks to an arm-free system that offers unprecedented freedom of movement.

- Versatile measurement capabilities: Measure objects of any size or geometry with confidence.

- Take it anywhere: The system, tripod and accessories fit into a single, portable carrying case for easy travelling to remote production sites.

Simplicity that Gets the Job Done

Quality control teams rely on the HandyPROBE’s fast setup time and ease of use to quickly carry out mission-critical inspections and accelerate production.

- No rigid setup required: The system can be moved freely in a larger and extendable measurement volume and mitigates conventional leapfrog that occurs with traditional portable CMMs.

- Automatic alignments: Optical reflectors allow for repetitive inspections without bogging down processes with realignment.

- User-friendly design: The ergonomic wireless probe and multi-function buttons make for faster onboarding and easier interaction with the system.

- Optional 3D scanning capabilities by adding the MetraSCAN 3D

Applications

The HandyPROBE Next portable CMM enables highly accurate measurements directly on the production line.

Inspection and Quality Control

- First article and supplier quality inspection

- Part-to-CAD analysis

- Evaluation of conformity of manufactured parts against the originals

- Evaluation of conformity of 3D models against original parts/production tooling

- Alignment

- Tooling certification

- Complete free-form inspection and high-density color maps when used with a MetraSCAN 3D

- Multi-shot measurements (up to 30 points/second)

Reverse Engineering

- Quicker and more accurate reverse engineering of combined parts (free-form and geometrical) when used with a MetraSCAN 3D optical CMM scanner

- Reverse engineering of geometrical entities (cylinders, planes, spheres)

Industries

- Automotive/transport

- Aerospace

- Heavy industries

- Consumer products

- Manufacturing

- Research and education

- Power generation

HandyPROBE Next TECHNICAL SPECIFICATIONS

| HandyPROBE Next | HandyPROBE Next | Elite | ||

| ACCURACY | 0.030 mm (0.0012 in) | 0.025 mm (0.0009 in) | |

| VOLUMETRIC ACCURACY | 9.1 m3 (320 ft3) | 0.086 mm (0.0034 in) | 0.064 mm (0.0025 in) |

| 16.6 m3 (586 ft3) | 0.122 mm (0.0048 in | 0.078 mm (0.0031 in) | |

| VOLUMETRIC ACCURACY (with MaxSHOT 3D or C–Link) (2) | MaxSHOT Next | 0.060 mm + 0.025 mm/m (0.0024 in + 0.0003 in/ft) | 0.044 mm + 0.025 mm/m (0.0017 in + 0.0003 in/ft) |

| MaxSHOT Next | Elite | 0.060 mm + 0.015 mm/m (0.0024 in + 0.00018 in/ft) | 0.044 mm + 0.015 mm/m (0.0017 in + 0.00018 in/ft) | |

| MEASUREMENT RATE | 80 measurements/s | ||

| PART SIZE RANGE (recommended) | 0.2–6 m (0.7–20 ft) | ||

| SOFTWARE | VXelements | ||

| WEIGHT | Probe: 0.5 kg (1.1 lb) C-Track: 5.7 kg (12.5 lb) |

||

| DIMENSIONS (LxWxH) | Probe: 68 x 157 x 340 mm (2.7 x 6.2 x 13.4 in) C-Track: 1031 x 181 x 148 mm (40.6 x 7.1 x 5.8 in) |

||

| OPERATING TEMPERATURE RANGE | 5–40°C (41–104°F) | ||

| OPERATING HUMIDITY RANGE (non-condensing) | 10–90% | ||

| CERTIFICATIONS | EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE | ||

| PATENTS | FR 2,838,198, EP (FR, UK, DE, IT) 1,492,995 | ||

| CERTIFICATIONS |

EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE (1) HandyPROBE Next and HandyPROBE Next|Elite performance assessment (ISO 17025 accredited) is based on partial procedure per ISO 10360-12 standard: Probing size error (6.2) and Length error (6.4). Performance is assessed on traceable sphere and length artefacts. (2) The volumetric accuracy of the system when using a MaxSHOT 3D cannot be superior to the default accuracy for a given model. |

||